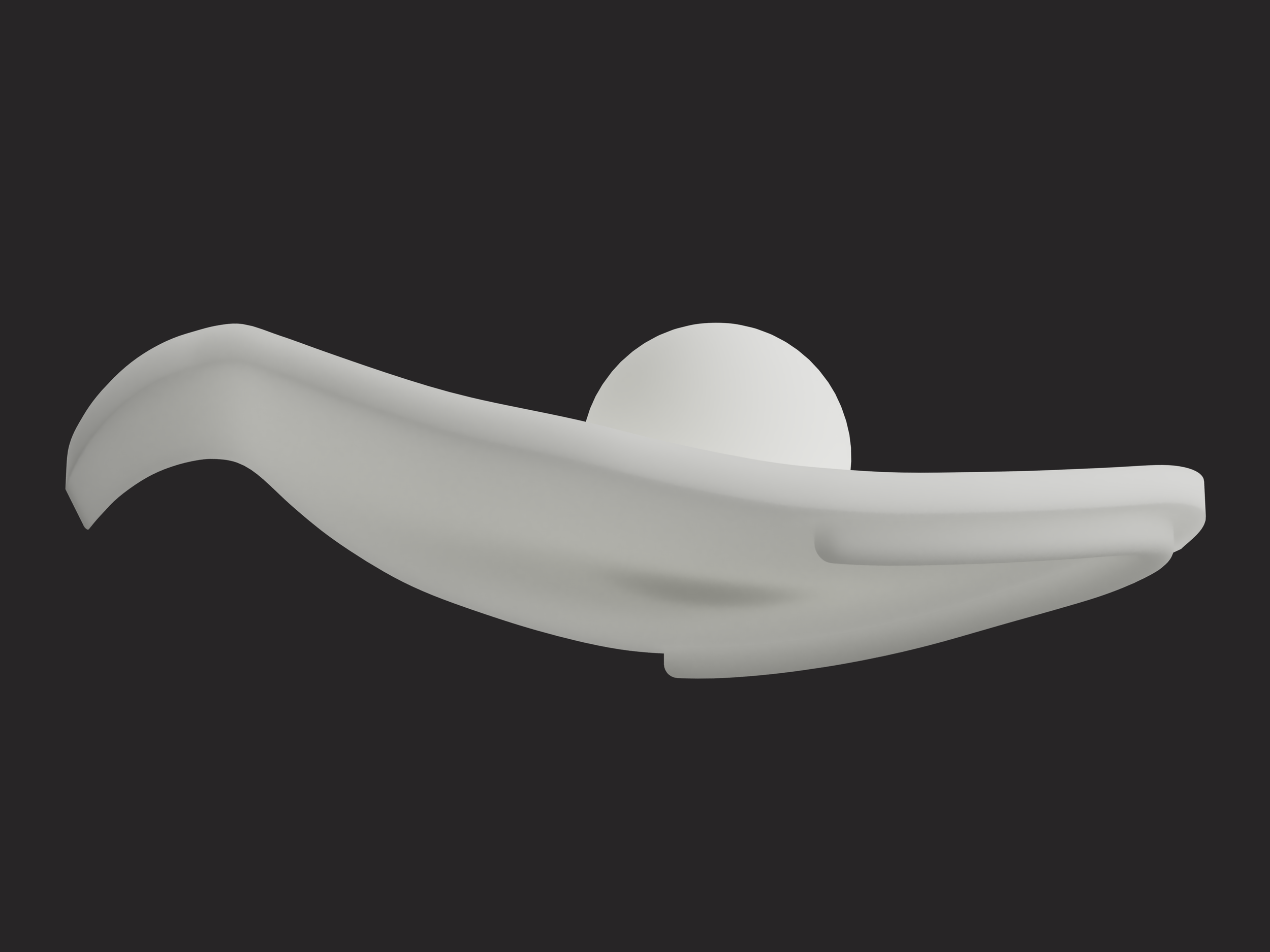

Pitcher Lid

An elegant solution to a simple problem.

When weather permits, my family loves to eat meals outdoors, and one evening when I reached for the pitcher to refill my glass of water, I noticed a couple bugs swimming in the drink! This was unacceptable, so I had no choice but to rectify the situation in the only manner I know how: spending hours modeling a lid for this handmade, asymmetrical pitcher.

Pitcher Photos

By taking two photos of the pitcher, one from a top-down perspective and the other of the pitcher’s side-profile, I was able to reconstruct the geometric constraints of the top of the pitcher. Importing these two images into Fusion 360, superimposing them onto each other in their respective axes, and then scaling them so they are the accurate size, I was able to create splines along the main contours of the pitcher that enabled me to generate a shape. Once I had the geometries all established, I printed the lid using a standard FDM 3D printer.

Methodology

Using the side-profile image, I created another spline that perfectly aligns with the curvature of the pitcher’s side.

While I could be done here, I added a few details to make the user experience of the pitcher lid more elegant. On the bottom of the lid is a little protrusion that goes around the back half of the pitcher’s inner perimeter. This protrusion fits snuggly into the pitcher, keeping the lid in place and in the correct orientation when it is on the pitcher.

I started with the top-down view. I manually created a spline that goes around the edge of the pitcher and then extruded the body from that blue profile.

By using the intersection of the top-down body and the side-profile area, I was able to generate a shape that perfectly fits atop the pitcher.

With a small spherical handle on top, the lid can be easily lifted and moved before somebody is about to pour their drink.